Requirements

Different surface characteristics lead to variable process conditions when processing welding wire. The required, absolute cleanliness of the wire surface also results in challenging feeding conditions.

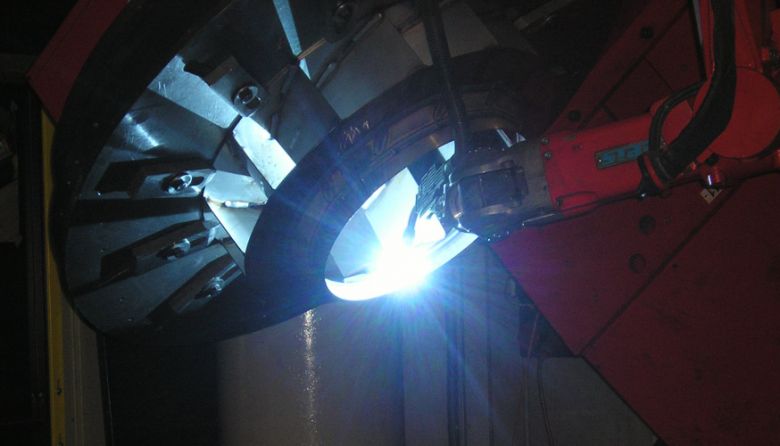

Compared with dynamic friction, an increased static friction may cause issues during starts and in extreme cases, this may also result in arc ignition faults or burn-backs.

An unfavourable current transfer also leads to side effects including micro arcs in the contact tip.

An absolutely clean wire with perfect feeding and arc ignition characteristics is paramount.

Benefits

Using PROTEC WLS brings about considerable benefits:

- Process safety, even in critical processes

- Increased service life of wearing parts (liner, contact tip)

- Increased productivity by reducing downtime

Application by the wire manufacturer brings about additional benefits:

- Improved layered coils and barrel coils

- Corrosion protection

- Guaranteed top wire quality

Application

- Suitable for application during processing or by the wire manufacturer

- Easy to apply using PROTEC Wire-PAD and Wire-CLIP for wire processing

- Automated application using Wire-Coating-Station PROTEC

- A minimum layer of PROTEC WLS fluid on the wire surface is sufficient to ensure ideal effects

Safety

- Purification for absolutely clean wire surface

- Reduces friction and wear, improved feeding characteristics

- Improved current transfer and arc ignition characteristics for wire electrodes, prevents micro arcs in the contact tip

Applying PROTEC WLS results in a stable arc with optimum arc ignition characteristics